As we look to the year 2025, accuracy and repeatability have never been more important to lab testing instruments. These tools are very important for proving the right durability levels of the product, along with safety standards, and research activities in various sectors and industries.

Nonetheless, it has become evident that the right choices of lab testing instruments are vital with increasing technological systems to uphold high standards and operational excellence. This guide covers the most advanced and efficient lab testing instrument to be used in the year 2025. These instruments are used to cater to the needs of contemporary research laboratories as Operational

Tools that enable the attainment of increased product quality, optimized processes, and innovation.

From mechanical testing to quality assurance and physical research, these instruments offer the accuracy necessary for a winning edge in today’s highly kinetic manufacturing environment.

Top 10 laboratory testing instruments

Find the top 10 laboratory testing instruments for 2025 and their excellent performances and accuracy. The industrial testing instruments are also designed to support the latest laboratory and industrial demands.

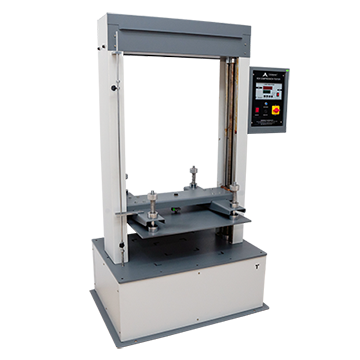

Box Compression Tester

A Box Compression Tester is one of the crucial lab testing equipment for compressive strength testing of packaging materials. This tester simulates natural conditions to determine how cardboard boxes and other materials respond to pressure and ensure durability while in storage and shipping.

The top features:

- Extensively used in packaging and logistics.

- It prevents damage to products during transport.

- The future trends would be more automation systems for testing in real-time.

Vacuum Leak Tester

The Vacuum Leak Tester detects leaks in packed and sealed pouches or containers, ensuring that the packed product in them, such as pharma, electronics, etc., is damage-free. This laboratory testing equipment is highly essential in assuring the present high standards in packaging technology.

The top features:

- It Notes even the tiniest leak in the packaging.

- It Protects against contamination, which is much needed in food or pharma industries.

- Its improved accuracy by using technology with the help of sensors from IoTs.

Bursting Strength Tester

Busting strength tester is a kind of tester that tries to check a material, that is, for how much strength a material -paper or plastic- can work before bursting off. This one is an integral part of packaging as it delivers safe transportation through the packaging method.

The top features:

- Determine which material for the packaging for the product.

- Secure and safe means in packaging measures.

- There is a rise in eco-friendly packaging. There might be more testing for new biodegradable materials.

Scuff Resistance Tester

This laboratory test equipment tests the resistance of materials like plastics, coated papers, and fabrics to surface abrasion. Scuff Resistance tester mimics the handling and transport processes so that the products reach the markets in good quality as well as appearance.

The top features:

- It is very important for the package and printing industries.

- It helps prevent degradation of products due to abrasion.

- Soon, scuff resistance tests are going to be improved through higher sensitivity, thus more material sustainability would come along.

Edge Crush Tester

Strength of corrugated materials is given by the edge crush resistance tester where corrugated material under pressure at its edges determines its effectiveness in packaging against stress which may be developed during storage and transport.

The top features:

- Whether packaging material has strength becomes important.

- Helps to identify packaging designs that will be strong while at the same time being affordable.

- It will be possible by 2025 through enhanced automated testing

Salt Spray Tester

A Salt Spray Tester simulates corrosive environmental conditions to test the resistance of metals and coatings. This laboratory testing equipment is essential in industries whose products are exposed to severe environments, including automotive and aerospace.

The top features:

- Simulates saltwater exposure to test the durability of materials.

- Guarantees that products can withstand environmental wear and tear.

- Emerging trends indicate the advancement of more controlled, high-precision chambers for more accurate corrosion testing.

Tensile Testing Machine

A Tensile Testing Machine measures the tensile strength of a material, or how much resistance the material has to being pulled. In a lab testing machine, a tensile tester finds out how much a material can take when tension and tension and stress are applied.

The top features:

- How materials resist being pulled on.

- Materials are safe for use.

- Future automation of real-time measurement with finer granularity.

Melt Flow Index Tester

The Melt Flow Index Tester measures the flow rate of melted plastic, indicating how easily the material will flow during processing. This is one of the important tools for material behavior in the manufacturing process.

The top features:

- Evaluates polymers for moldability and processability.

- Guarantees constant production quality.

- Next-generation testers, which are expected to come in 2025, will feature more precise digital controls and automated systems for high-speed testing.

Coefficient of Friction Tester

This tester measures friction between two surfaces. COF Tester offers manufacturers knowledge in terms of the slip resistance of such products as footwear, flooring materials, and package materials.

The top features:

- Assesses surface interaction and wear resistance.

- Critical for products like anti-slip flooring and packaging materials.

- Innovations in friction testers will focus on measuring dynamic friction in varying environments, improving material selection.

Top Load Tester

A Top Load Tester tests the strength of a material or packaging against a load applied from the top. This is one of the significant tools for any packaging and logistics industries that stack up their products and manage them.

The top features:

- Product integrity under pressure

- Optimization of the design of the package

- Future trends: More automation of the testing processes will speed it up and also make the test process more accurate.

Conclusion

When the digital year 2025 starts, the reliance on lab testing instruments can be vital, helping get the desired precision, quality, and safety. These advanced tools term as not only tools considered as equipment but as integral to innovation, improving and making business processes durable. By equipping their laboratories with the latest lab testing instruments industries can succeed in providing the international market with accurately tested premium quality products.